Most drains and sewer pipes for domestic and light industrial use are 4 inch (100ml) and 6 inch (150ml), going up to and beyond 9 inch (225ml). Blockages can occur anywhere along the length of the pipe, for any number of reasons – from soft tissue expanding as it absorbs water, like throw away nappies, to debris clinging to obstructions like tree roots that have grown into a drainpipe or sewer – and clearing them can involve a number of methods from the spinning nozzles to root-cutting devices with saw blades attached.

Water jetting at up to 4000psi will clear most blockages, the nozzles having forward and reverse jet patterns to break up the blockage and then flush away the debris.

Click here to see a video of jetting a drain.

After clearing the blockage the pipe is cleaned using the water jetting machine with different nozzles. A good survey of the clean pipe can then be undertaken (with our drain inspection cameras!) to establish that no further obstructions remain to cause future blockages. This will often be required for insurance purposes, with many insurers demanding the original, blocked pipe survey to compare against.

Jetmasters provides all the equipment needed for drain cleaning and surveying, from the simple drain-rods to all types of jetters to camera inspection equipment with recorders to show owners/occupiers that the job is done and is all clear.

The Drain & Sewer Cleaning Course gives the trainees a full appreciation of the problems that may be encountered and the different methods of overcoming the difficulties by using the correct pressures, nozzles and accessories to ensure that the task is carried out safely & efficiently. After the theoretical session, including a questionaire, is completed in the classroom the trainees are then moved outside to carry out the practical part of the course.

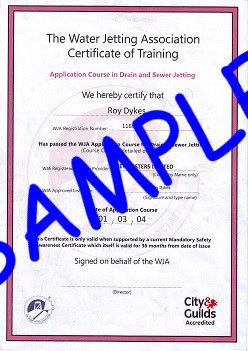

Certificates are issued to those trainees who reach the required standards and do NOT need renewing. However, to be valid it MUST be accompanied by an in-date Safety Awareness Certificate and Photocard.

Please visit the Book Courses page to book training courses.

Go back to the Safety Awareness page course to review.

You can see the Drain & Sewer Cleaning Certificate issued by the Water Jetting Association on this page, it is awarded to successful candidates passing the practical test and completing the questionnaire. This certificate only has to be taken once and it remains valid as long as a valid Safety Awareness Certificate is in force.

You can see the Drain & Sewer Cleaning Certificate issued by the Water Jetting Association on this page, it is awarded to successful candidates passing the practical test and completing the questionnaire. This certificate only has to be taken once and it remains valid as long as a valid Safety Awareness Certificate is in force.