Health and Safety within the water jetting industry is of paramount importance, trained staff will have a greater awareness and appreciation of safe working practices with high pressure water jetting. Councils, insurance companies, water utilities and major contractors all demand that staff have the correct training and hold valid Certificates.

A number of training courses are available, starting with the Safety Awareness Certificate. The Safety Awareness course is essential as it “Validates” the other courses. The certificate lasts for three (3) years. After three years, another Safety Awareness course must be taken and passed in order to re-validate other course certificates. If your Safety Awareness certificate goes out of date, for any reason, your other certificates immediately become invalid, which means useless! A valid Safety Awareness certificate is required to keep all certificates validated.

The Safety Awareness Certificate is the first course to be passed, then there are Surface Preparation, Drain Cleaning, Water Cutting and Tube Cleaning.

Please visit the Book Courses page to book training courses.

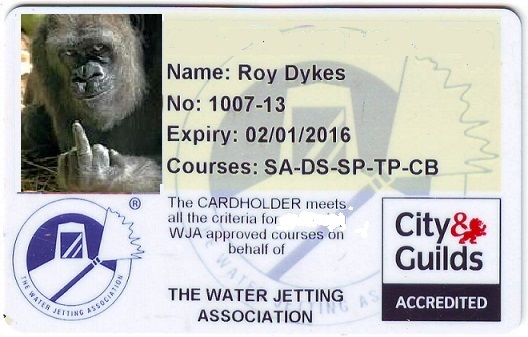

The Water Jetting Photocard

WJA Safety Awareness Training Course – Contents

1. REGISTRATION & INTRODUCTION

2. APPLICATIONS & MACHINES:

Cleaning & surface preparation – surfaces / drain & sewers / pipes / tubes. Jet cutting – precision and volume removal. Effect of varying pressure / flow at the nozzle. Range of jetting machines, configurations & categories (Pressure Washers / General Purpose / Medium-Heavy Duty / UHP / Drain & Sewer Jetters).

3. LEGISLATION & THE WJA CODES OF PRACTICE:

Health & Safety at Work Act. WJA Codes of Practice, status, use & recognition by the Health and Safety Executive (HSE). Management Regulations – Risk Assessment, PPE at Work Regulations, COSHH. Employer/ Employee responsibilities. Enforcement Powers. Other relevant legislation – e.g. Environmental Protection Act, Control of Pollution Act.

4. JETTING EQUIPMENT – NOZZLES:

Jet principles – purpose of nozzles, power of water jet, jet pressure/flow characteristics, jet reaction force. Types of nozzle – forward facing, fixed & spinning jets, multi-jet fixed & jet spinning nozzles.

5. JETTING EQUIPMENT – PUMPS:

Pump configuration – standard piston ~ plunger pump, positive displacement action, operating features, effects of blockages, variation of plunger sizes. Other pump configurations, diaphragm and intensifier types. Drive arrangements, engine / electric motor, hazardous area equipment Water supply/delivery features – filtration requirements, boost feed pumps, pulsation dampeners, jump-jet. Pressure safety relief options – relief valve / bursting disc. Pressure gauge features.

6. JETTING EQUIPMENT – PRESSURE CONTROLS:

Dump & dry shut controls, fail-safe / selector versions, direct manual operation / remote operation via electric-pneumatic-hydraulic controls, automatic unloader valve for dry shut, pressure regulators, automatic off-load engine speed control systems.

7. JETTING EQUIPMENT – HIGH PRESSURE HOSE:

Hose construction & pressure ratings, external & internal damage possibilities, hazards arising from damaged hoses, inspection requirements. Hose end fittings, construction / assembly / testing. Connectors & hose end couplings – types & features. Bore size & flow ratings. Hose for general / high flow / small bore tube & pipe cleaning. Pressure drop due to flow through hose & lances – effect on pressure available at the nozzle.

8. WATER JETTING HAZARDS:

Hazards arising – directly from the water jet – from operational regime – from site environment.

9. WATER JETTING INJURIES:

Effects of impact by high pressure water jet, nature of internal injuries caused, action in event of a jetting injury -awareness of possible absence of visual injury & use of WJA Medical Card.

10. PERSONAL PROTECTIVE EQUIPMENT:

General principles regarding use of PPE, as a last resort. Main body protection – limits on effectiveness against direct impact of water jet. Protection of head / hands / feet / hearing / respiration. Particular requirements when using UHP.

11. OPERATIONAL PROCEDURES:

Routine care & inspection, site preparations, preparations for operation, team operation. Safety points during operation – use of manual jetting gun/lance, tube/pipe/drain cleaning nozzle/lance/hose combinations & techniques. Safe use of non-standard equipment – e.g. tee nozzle. Site shutdown & antifreeze procedures. Use of Do/Do Not Guide.

12. SUMMARY:

Review of course content as above, with opportunity for any further discussion before Questionnaire.

This is the current version of the Safety Awareness Certificate.

The Pressure Washing Certificate